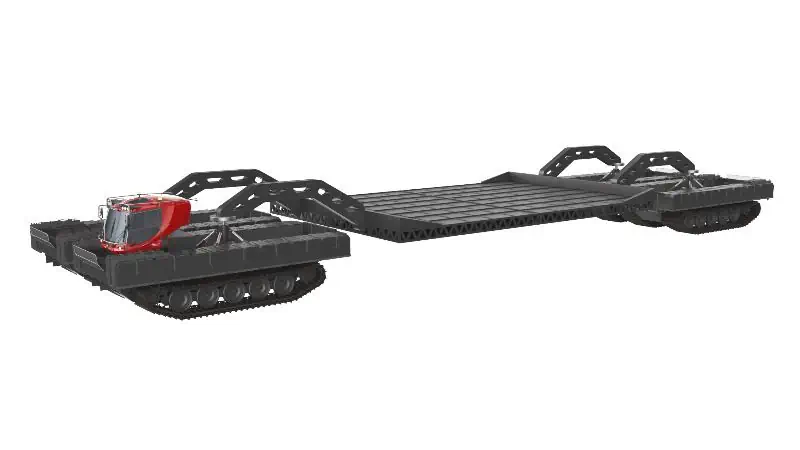

Industrial exterior design and configuring of the wheeled all-terrain vehicle

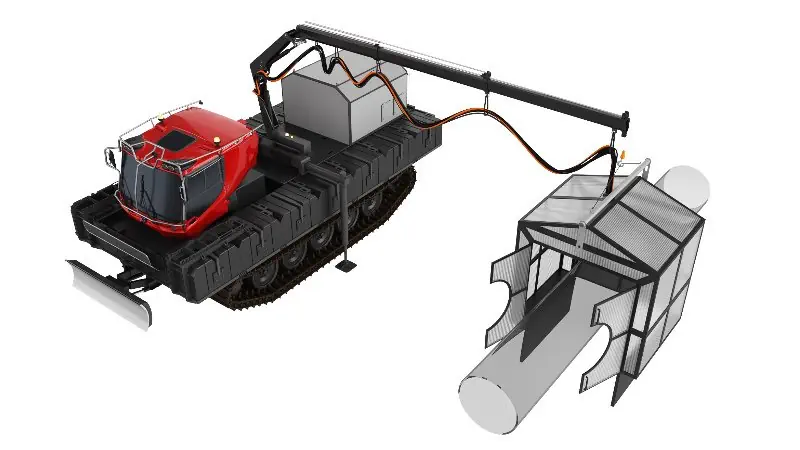

The goal of the project was to make an all-terrain vehicle's design match an existing chassis and a standard driver's cab body (as it sets the design style).

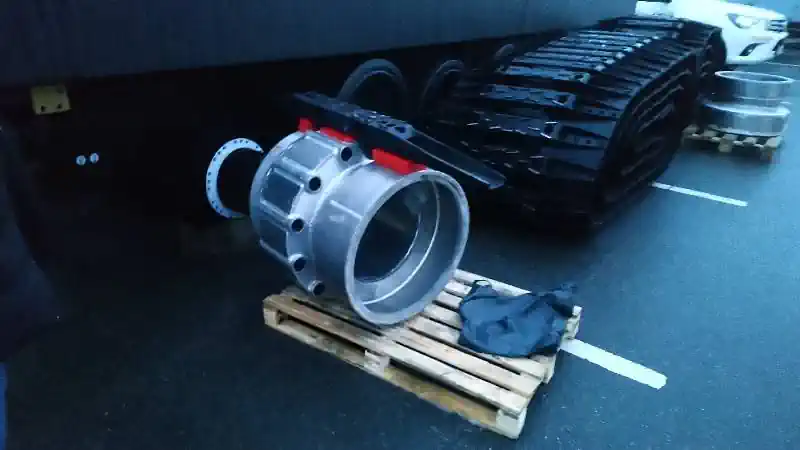

It was necessary to develop a visual style and design of the car front, taking into account special conditions of its operation and dimensions. Since the height of the wheel is 1.6 meters, it was necessary to ensure the ability to stand on the surface of the wheel arches and bumper to provide access under the hood. The vehicle is meant to be used in remote areas, including those within the Arctic Circle, therefore it must be adapted for repair outside the service station.

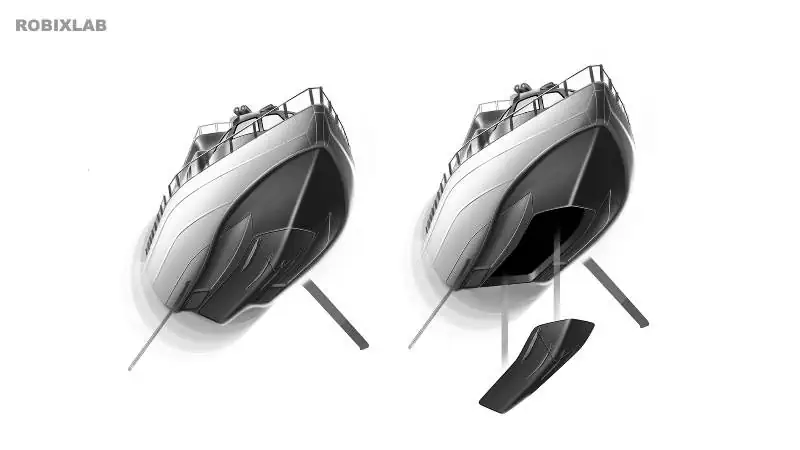

Wheel arches are removable, since smaller wheels are used for movement on public roads (to reduce size). All lighting equipment is made using transparent armour and functions in two modes, optimized for large and small wheels. The engine compartment is protected from below by a sloped armor plate merging into a power bumper, also of importance is a winch mechanism inside.

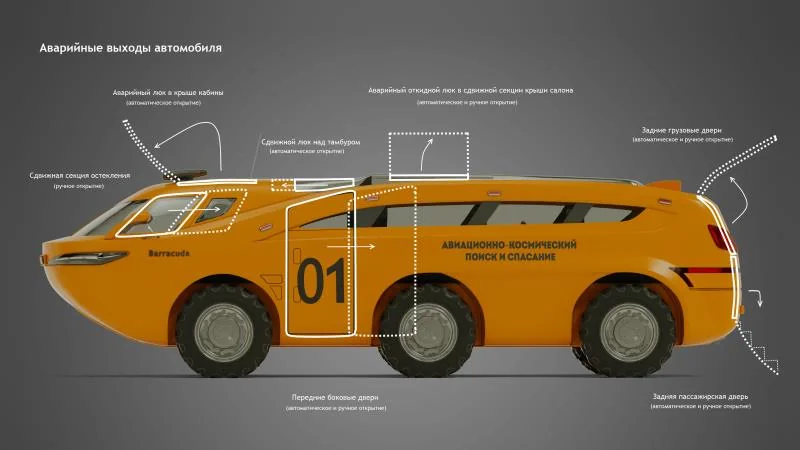

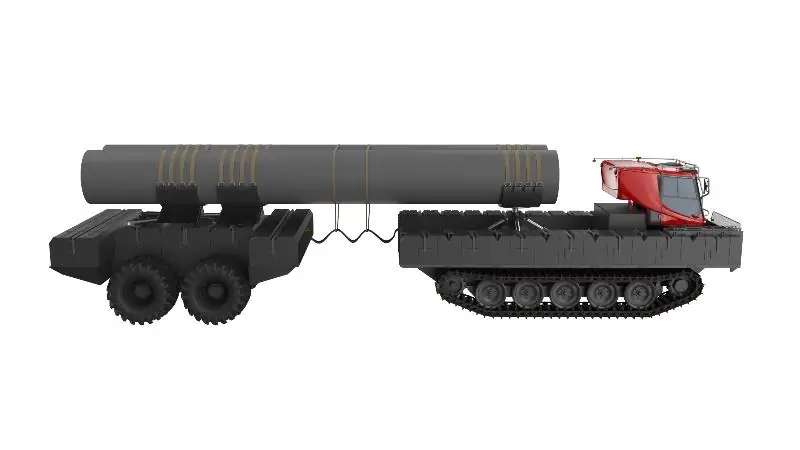

Also the bodies of functional modules are developed for being placed in a vehicle: i. e. passenger and process ones.

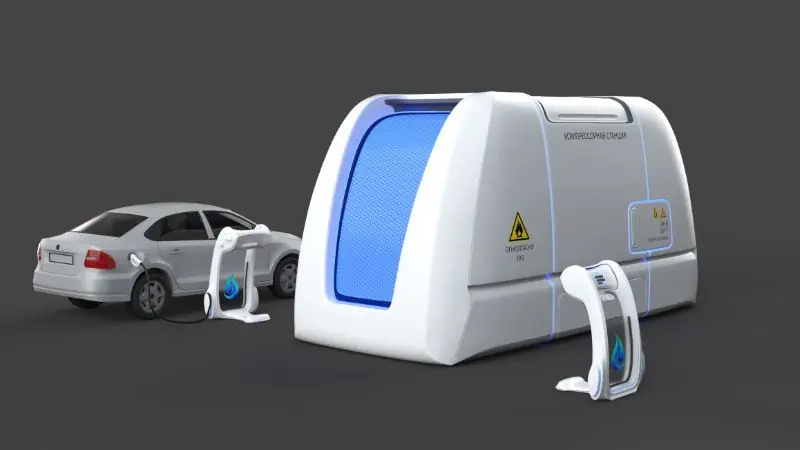

The passenger module allows you to transport a team of workers and is used for household purposes; a version for long-term residence and housing in it is possible as well. Its body design provides for thermal insulation and special onboard systems for autonomous operation at temperatures up to -60 degrees Celsius.

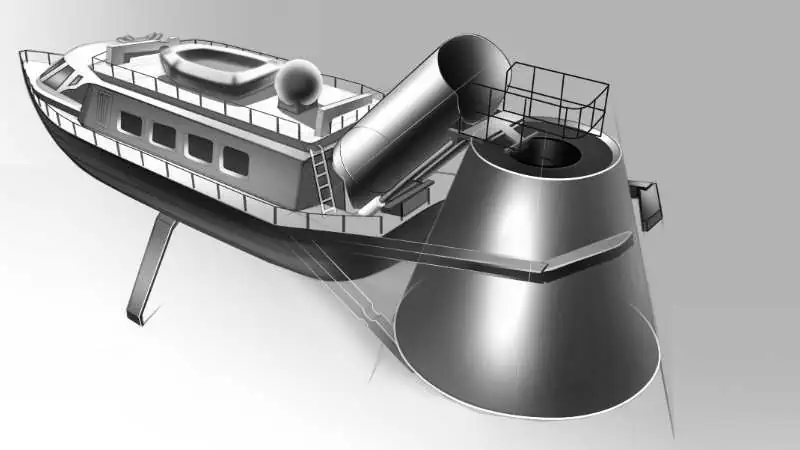

The process module is designed to accommodate workbenches and medium-sized equipment at the table level. Since the lower corners of the module's body are not used, we chose a non-standard truncated shape for it, which made it possible to increase the height of the process module's internal space while the height of the vehicle remained the same.